Permanent Jewelry Jump Ring Guide for Beginners & Pros

When I first started my permanent jewelry business, the whole idea of jump rings confused me. It seemed complicated to figure out which ones were the best for each size of chain. But after some time researching and learning more about it, everything started to make sense. Choosing the right jump ring for welding permanent jewelry became a lot easier, and now I want to help make it easier for you too.

In this guide, we’re going to talk about everything you need to know about jump rings, which might seem small but are super important in welding jewelry, especially for pieces meant to last forever. You’ll learn about the different sizes, why quality matters, and what kinds of metals to use. I’ll also point you to some good places to buy them. And if you like doing things yourself, I’ll even show you how to make your own jump rings to add a personal touch to your work.

This guide is here to help you get a good handle on choosing jump rings, making welding permanent jewelry easy, convenient, and profitable. Whether you’re just starting out or you’ve been welding jewelry for a while and want to get better at it, stick around. Let’s get into how to pick the perfect jump rings for your permanent jewelry, making sure each piece is not only gorgeous but also strong and lasting.

We foster relationships with brands we use and trust. The testimonials on our site represent real experiences, but they don't guarantee you'll achieve similar results. When you make purchases through our links to our partners, we may earn a commission. Your support helps us continue this work. You can read our full disclosure here.

Related: Best Online Permanent Jewelry Training Courses

Understanding Jump Rings

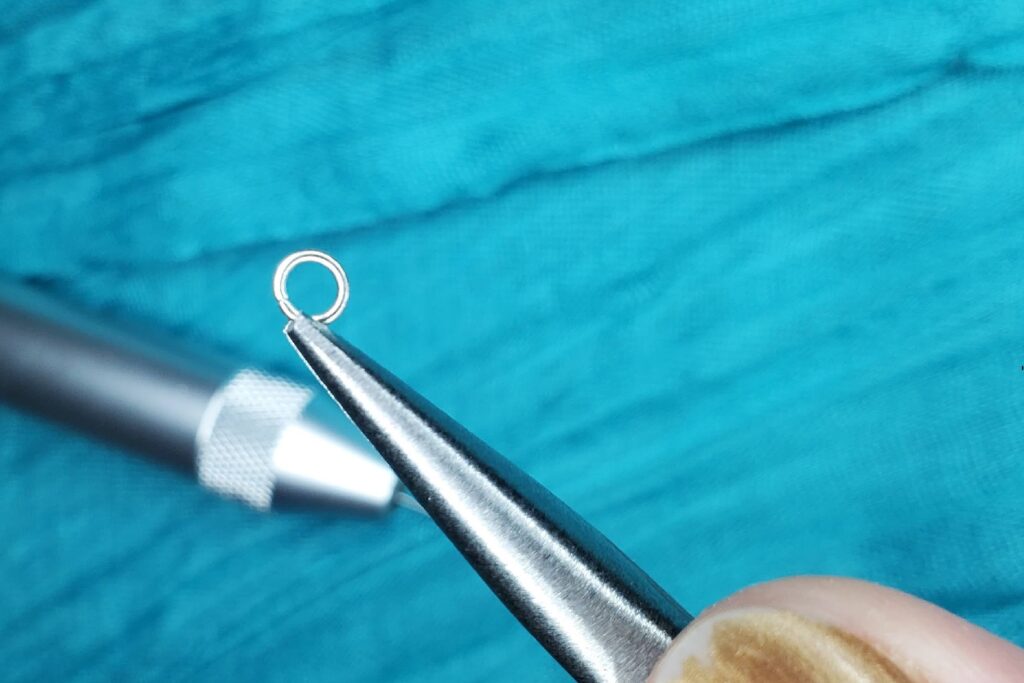

Jump rings are those tiny loops you see in necklaces, bracelets, and other kinds of jewelry that help hold everything together. Think of them like the little links that keep the parts of your jewelry connected. They come in different sizes and thicknesses, and you’ll run into a few types, like the ones that snap open and shut, thicker ones that are simply twisted closed without a welder, and ones that are welded together to form a closed loop.

When we talk about using jump rings in permanent jewelry, picking the right jump ring is important. You want something that’s not just good-looking but also strong and able to last a long time without breaking. For permanent jewelry, the kind of jump ring that gets welded shut is the No. 1 choice because it’s especially secure. Once it’s attached, it’s meant to stay put, keeping your jewelry pieces permanently intact.

Sizing

When picking out jump rings for your jewelry, the size really matters. You’ve got to think about how big or small they are so they match up right with the rest of your jewelry, like the chains you use. If a jump ring is too big, it might look out of place, or if it’s too small, it might not fit or be strong enough to hold things together.

Gauge

The gauge of the wire tells you how thick the wire is, and you’ll need to become familiar with each one to know whether the jump ring will fit into your chain links. Basically, if the gauge is too large, you will not be able to loop it through tiny links, and if it’s too small, it may become frail. This thickness will be the determining factor in keeping your jump rings round and strong or watching them stretch and become oblong over time.

Diameter

The diameter of a jump ring is the total size from one outer edge to the other. This measurement is crucial because you don’t want it to be much larger than the size of each chain link. If it is, the jump ring will stick out like a sore thumb, making the jewelry piece look awkward and unbalanced.

Aspect Ratio

To get a bit more technical, there’s something called the aspect ratio, which is just a fancy way of talking about the relationship between the thickness of the wire and the diameter of the jump ring. This ratio can really affect how the jump ring fits with your design and how it moves or hangs. For example, a thicker wire with a small diameter might be great for a charm that you don’t want moving around too much, while a thinner wire with a larger diameter might be perfect for a looser, more flowing design.

Now, you might be wondering how you’re supposed to measure the chains to find the perfect jump ring. A super handy tool for this is a digital caliper. It lets you get precise measurements of your chain links, so you can pick the right size of jump ring every time. With a digital caliper, you can measure the inner dimensions of your chain links to ensure the gauge of your jump ring will fit just right.

Ready to become a LINKED certified permanent jewelry artist? Use the discount code TRINITYTPAHP at checkout to get started!

Related: Best Permanent Jewelry Welders

Metal Type and Quality

Selecting the appropriate metal for permanent jewelry jump rings is critical, particularly when it involves welding them shut. I want to emphasize the superiority of solid 14k yellow gold and solid 14k white gold jump rings for such applications, highlighting the significance of metal quality.

For your gold chains, opting for solid 14k yellow gold jump rings is recommended. And for sterling silver or stainless steel chains, solid 14k white gold jump rings are best. The advantage of using solid gold jump rings lies in their integrity upon welding; they do not reveal any base metal beneath. This characteristic is key to the longevity and appearance of your customers’ permanent jewelry.

The issue with gold-filled jump rings, despite their appealing look and lower cost, becomes apparent during the welding process. Welding a gold-filled jump ring might initially seem successful, but a small dark spot at the weld point often appears. This discoloration occurs as the heat exposes the base metal within the jump ring, rather than the outer gold layer. Over time, this dark spot can enlarge, weakening the metal and potentially leading to breakage or unsightly corrosion, which is not the same thing as tarnishing.

That’s exactly why I personally use and recommend solid gold jump rings, either in white or yellow gold, even if the chains I’m using aren’t solid gold. Using solid gold ensures that the whole jump ring is made of the same high-quality metal, so when it’s welded closed, there’s no chance of any lesser metal being exposed and ruining the look or strength of the connection.

Related: Will Permanent Jewelry Tarnish? (Here’s What You Can Do)

Where to Buy Jump Rings for Permanent Jewelry

If you’re in pursuit of high-quality jump rings suitable for permanent jewelry applications, there are several reputable suppliers known for their exceptional products and services. Understanding where to source these critical components can significantly impact the durability and appearance of your jewelry. Here is an overview of key suppliers in the industry:

- Pepetools: Renowned for providing a comprehensive range of jewelry making tools and materials, Pepetools is an ideal website for those looking for high quality jump rings. They cater to both beginners and seasoned professionals, offering solutions that ensure precision and efficiency in jewelry making.

- Imprinted Supplies: Specializing in custom imprinted and specialty jewelry supplies, Imprinted Supplies offers an array of jump rings that can be tailored to meet specific design requirements. Their focus on customization makes them a valuable resource for creating unique and personalized jewelry pieces.

- Stones & Findings: This supplier boasts a diverse selection of jewelry findings, including jump rings in various metals and styles. Their inventory is suited to a wide range of design aesthetics, from classic to contemporary, providing options for every type of jewelry welder.

- Mojo: With a commitment to quality and durability, Mojo stands out for its comprehensive selection of jewelry-making supplies. Their emphasis on high-grade materials ensures that the jump rings sourced from Mojo will contribute to the longevity and integrity of permanent jewelry pieces.

Ready to become a LINKED certified permanent jewelry artist? Use the discount code TRINITYTPAHP at checkout to get started!

Related: The Best Permanent Jewelry Chains & Supplies

Make Your Own Jump Rings

Understanding the nuances of jump ring size and metal quality is just the beginning. With this knowledge, you have the power to not only choose the best jump rings for your projects but also to make the right size and quality jump rings yourself. With some gold wire, a pair of flush cutters, and round-nosed pliers, making your own jump rings is simple. This guide has equipped you with the insights needed to determine the correct size of jump rings for your chains, ensuring a perfect fit every time.

While the process of creating your own jump rings demands more effort and time compared to the convenience of purchasing them online, the cost savings over time can be substantial. This is especially true if you’re welding a high volume of permanent jewelry pieces. If you’re serious about welding permanent jewelry, the ability to produce your own jump rings might just be the game-changer you need. But if you’re not ready to learn put that new skill on your plate, then purchasing them is just as effective.

Related: How Much Does it Cost to Start a Permanent Jewelry Business?